Enhancing Communication Between Designers and Manufacturers with GD&T

Geometric Dimensioning and Tolerancing (GD&T) is a system used in design and production that defines the allowed variations in type, positioning, and place of features on a part. It works as an universal language for engineers and makers, assisting to interact the style intent clearly and successfully. GD&T includes a collection of symbols that stand for numerous kinds of geometric control, which are crucial for ensuring component capability and manufacturability. Recognizing GD&T symbols and guidelines can substantially boost the top quality of design illustrations and add to smoother production procedures.To start with, GD&T symbols are standard and defined in the ASME Y14.5 standard, which indicates they have universal approval in engineering techniques. Monotony, represented by a two-dimensional sign, guarantees that a surface area is consistently level within specified limits, which is important for surfaces that require to secure or mate.

Discover GD&T symbols and guidelines the significance of Geometric Dimensioning and Tolerancing (GD&T) in design and manufacturing, as it boosts communication, accuracy, and cost-efficiency while reducing mistakes with standard symbols and guidelines.

Along with create controls, GD&T likewise consists of positioning controls, such as perpendicularity, parallelism, and angularity. These symbols gauge how much an attribute must line up with respect to an information reference. For instance, a perpendicularity control specifies that a surface area must go to a best angle to an additional surface within a defined resistance. Such controls are crucial in settings up where accurate placement is required, such as mechanical parts in a transmission system. Understanding just how to specify and interpret these positioning symbols is crucial for precise manufacturing and top quality engineering.

Area controls such as symmetry, setting, and concentricity are likewise crucial facets of GD&T. Finding out to use these location symbols effectively will aid engineers in accomplishing functional parts that satisfy style specifications while likewise simplifying the manufacturing processes included.

One more vital element of GD&T is the idea of information, which are referral factors or surface areas that act as a basis for dimension. The efficient use information is basic in making certain regular manufacturing top quality. Each information is appointed a letter classification, and it supports the component to market requirements, making sure that measurements are reputable and repeatable. Appropriately defined datums enable engineers to control variations more effectively, reducing the opportunity of mistakes in production. These recommendations assist in establishing a robust coordinate system that all tolerances can connect back to, making it crucial for any kind of layout designer to have a solid understanding of exactly how to make use of and create information recommendations.

The usage of GD&T in engineering drawings advertises more clear communication among stakeholders. When a developer defines tolerances making use of GD&T symbols, it lowers the uncertainty frequently associated with typical dimensioning techniques. This clarity help makers in comprehending the component needs precisely, thereby raising the probability of producing components that fulfill specs on the first effort. In markets where precision and top quality are critical, such as aerospace or medical gadget manufacturing, the duty of GD&T in enhancing communication can not be overemphasized. It connects the gap in between style intent and manufacturing capacity, guaranteeing that both parties get on the same web page concerning assumptions.

In addition, the application of GD&T is advantageous for price efficiency in production. Engineers who understand GD&T can considerably influence the cost-effectiveness of their styles without sacrificing high quality or efficiency.

In spite of its benefits, executing GD&T can be discouraging for those unfamiliar with the system. Inaccurate use can result in pricey mistakes in production and assembly, making correct training in GD&T principles necessary. Several educational sources, workshops, and training programs are now offered to aid engineers and designers discover the subtleties of GD&T. Such training often highlights the value of not only comprehending the symbols however additionally being able to apply them to real-world style circumstances. Practical applications of GD&T in case research studies can give insight into just how properly executed symbols bring about improved high quality and minimized scrap prices in production.

When editing or translating engineering drawings that utilize GD&T, attention to detail is critical. Standardization promotes a culture of high quality and consistency, enhancing the relevance of GD&T concepts in daily design method.

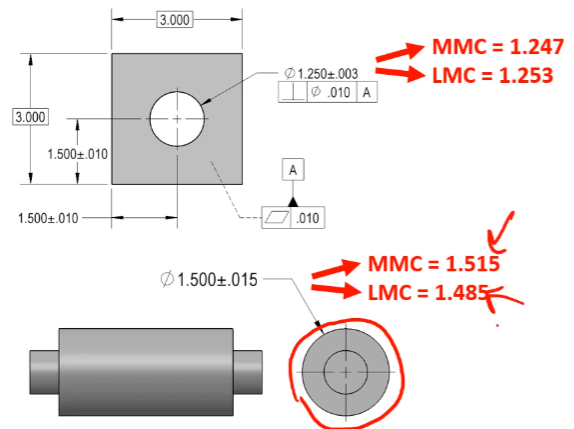

Discover mmb vs mmc the value of Geometric Dimensioning and Tolerancing (GD&T) in engineering and manufacturing, as it enhances communication, precision, and cost-efficiency while minimizing errors via standard symbols and guidelines.

In conclusion, mastering GD&T symbols and guidelines is a crucial ability for contemporary designers, specifically those involved in layout and production. By investing in correct training and exercising the effective application of GD&T principles, designers can take advantage of this effective device to drive development and quality in their styles, ultimately leading to an extra effective and competitive product growth lifecycle.